And that's not all: they also dissipate the heat produced during machining, protecting the tool and the workpiece from the harmful effects of high temperatures. These fluids also make it easier to evacuate the swarf produced during machining, preventing it from accumulating, which could compromise the surface finish of the machined part or lead to an incident. Finally, thanks to their anti-corrosion additives, they preserve metal surfaces, protecting them from rust.

Types of cutting fluids: whole oils and emulsions

There are two main types of cutting fluids: whole oils and emulsions.

Whole oils are undiluted oils, often derived from mineral, vegetable or synthetic bases, sometimes enriched with additives to optimise their properties. They are particularly well suited to processes requiring intense lubrication, such as bar turning, where their action protects tools, ensures a clean finish on machined surfaces and prevents premature wear.

Emulsions are a combination of two immiscible liquids: water and oil (generally between 3 and 10%), stabilised by an emulsifier. These cutting fluids are less expensive to buy and are particularly effective for cooling thanks to their high water content. However, their lubrication is inferior to that of full oils, they require regular maintenance and generally have a shorter service life.

Contamination of cutting oils

Whether in the form of whole oils or solubles, cutting fluids are loaded with contaminants during machining, such as ferrous metals, non-ferrous metals such as aluminium, or even precious metals. Filtration of these pollutants becomes essential, not only to clean up and recycle the liquid, but also to protect the cutting tools and extend their life. When machining precious metals, filtration of the cutting fluid enables the material to be recovered and re-melted so that parts can be re-machined, adding an economic dimension.

To choose the most suitable filtration system, a number of parameters need to be considered: the area of application, the layout of the workshop, the type and flow rate of the liquid, and the nature and concentration of the contaminants. Your objectives, whether in terms of recycling the liquid, decontaminating it, recovering precious materials or protecting and extending the life of your equipment, will also determine which filtration solution you prefer.

HIFI FILTER® offers a range of solutions to improve the quality of cutting fluids and guarantee optimum machine tool performance. These include automatic belt filters, EPC bag filters and FEC housings to capture the largest contaminants, avoiding premature saturation of in-line filters and extending their service life. At the same time, purification systems such as filtration units provide in-depth treatment of the oils. Finally, to maintain the performance of our equipment, we offer a wide range of spare parts, adapted to the specific needs of each installation.

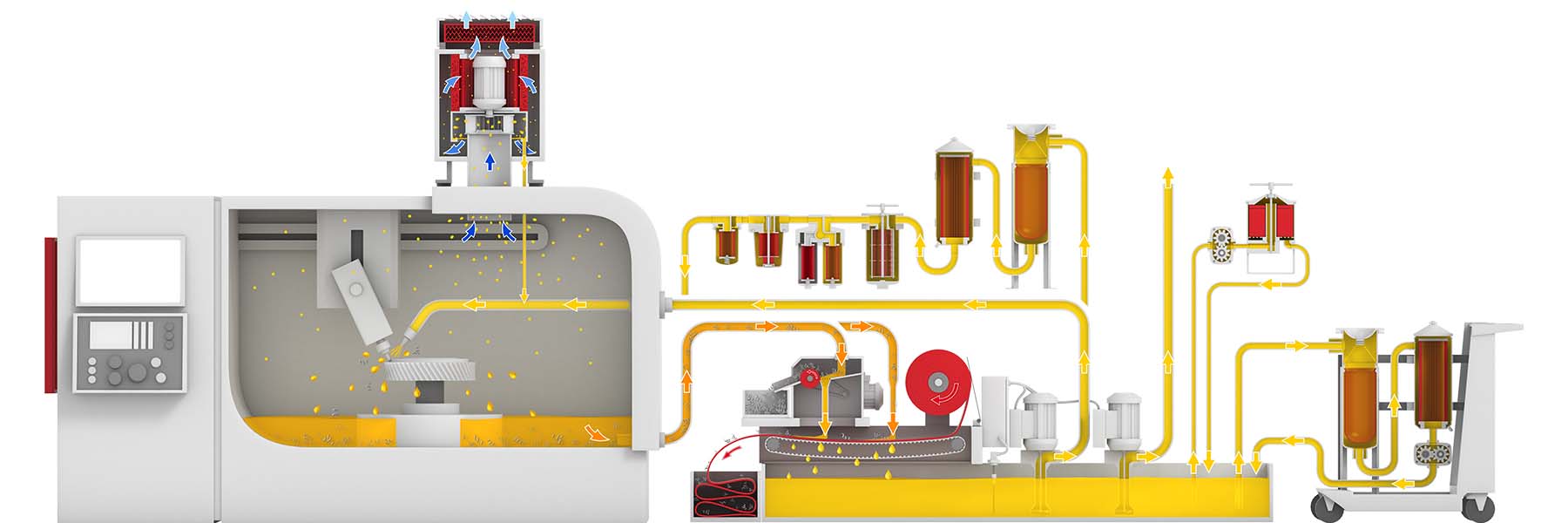

The automatic belt filter, commonly installed on machining centres, is a filtration device dedicated to industrial sectors generating a large volume of ferrous and non-ferrous contaminants.

The solid particles present in the cutting fluids are separated by a filter medium, allowing the chips to be recovered and the decontaminated fluid to be reused. This unit can be fitted with a magnetic separator that acts as a pre-filter, specially designed to eliminate ferrous and magnetic elements before the liquid reaches the filter belt. The process is simple: rotating magnets capture the metal shavings, which are removed by a scraper into a special tank. This pre-filtration reduces the cost of filter media.

The fluid then flows onto the filter belt, which advances automatically according to the level of cutting fluid. The volume of swarf accumulated on the filter medium raises the oil level in the PLC tank, activating a float sensor to trigger the advance of the filter belt. HIFI FILTER® also offers other types of sensor, such as pressure level sensors, providing alternatives adapted to each application.

For ease of maintenance, a sensor on the filter belt detects when the roll of media has run out and warns when it needs replacing.

💡 Depending on your application, rolls of filter media can be made of viscose, polyester, polypropylene, etc.

![Image non trouvée]()

Online filters

Where space is at a premium or to complement the PLC, and always with a view to improving fluid quality, the in-line EPC and FEC models are ideal.

The filtration thresholds for these two solutions range from 5 to 800 µm for the EPC and from 3 to 90 µm for the FEC. The EPC uses a filter bag and captures large contaminants in moderate quantities, while the FEC, with its pleated media, is better suited to small contaminants present in large quantities. In terms of throughput, the EPC supports higher volumes, ranging from 100 to 667 L/min, while the FEC is designed for more modest throughputs, between 70 and 140 L/min. Finally, these two filters share a notable feature: their filter elements are incinerable, enabling machining chips to be re-melted.

Spare filters: spin-on and switchable

HIFI FILTER also offers replacement parts for your original filters, including spin-on filters and replacement parts for switchable filters.

HIFI FILTER® in industry

HIFI FILTER also offers filtration solutions adapted to many other industrial sectors, in particular with its EL range, designed for the filtration of dielectric fluids and meeting the specific requirements of

electroerosion processes. Some filters in this range are incinerable, making it easier to recover machined precious metals. We also offer specific solutions for water jet cutting, guaranteeing clean water and preventing any risk of damage to equipment.

Whatever your needs, our advisors are on hand to help you identify the most appropriate filtration solution.