Railway equipment is exposed to extreme conditions. Its failure is costly and disrupts the network. Filtration is therefore essential to ensure its performance and availability.

Read more

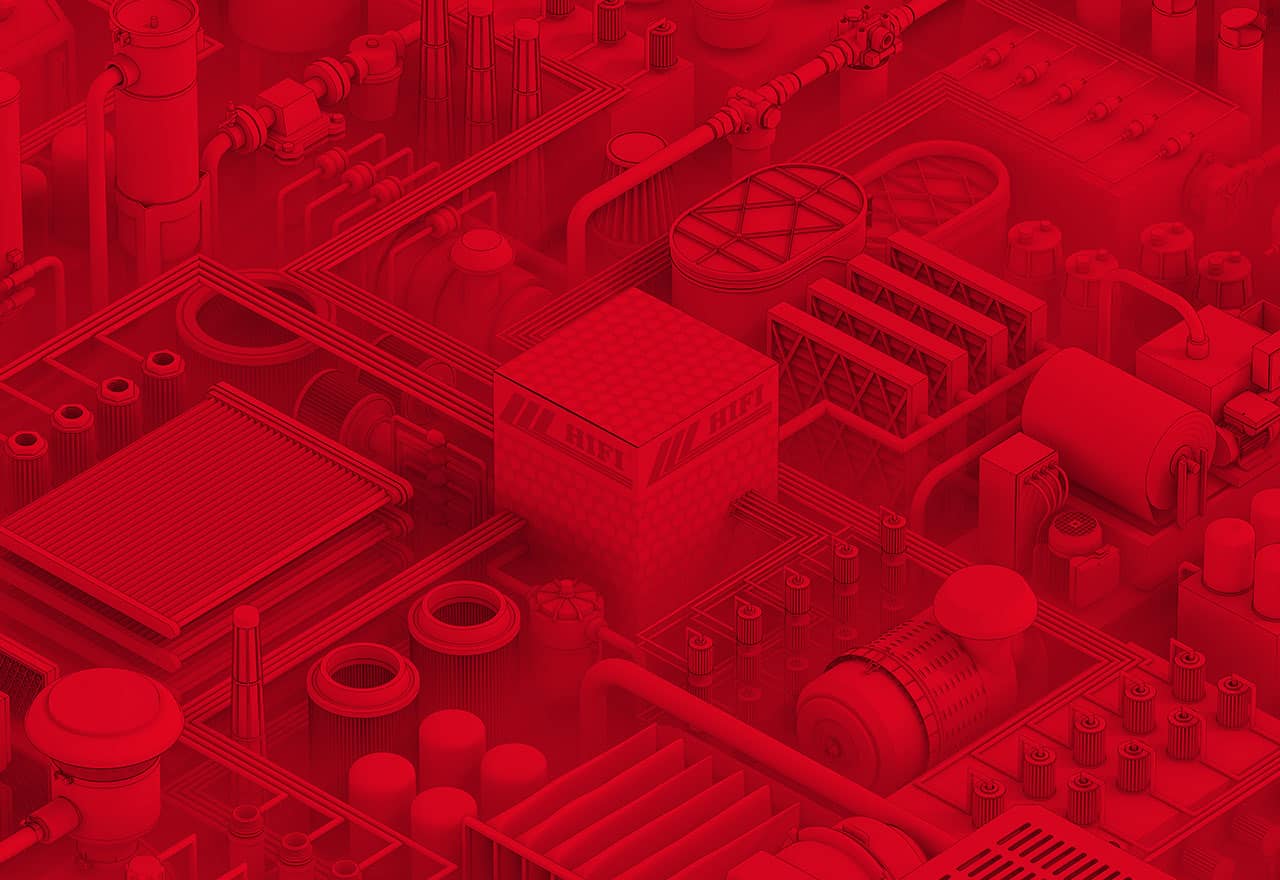

Looking for a filter, an application, an accessory?

E-Catalog

CATALOG.HIFI-FILTER.COM

24.10.2023

Why can't a water-absorbing filter be fitted to a vehicle?