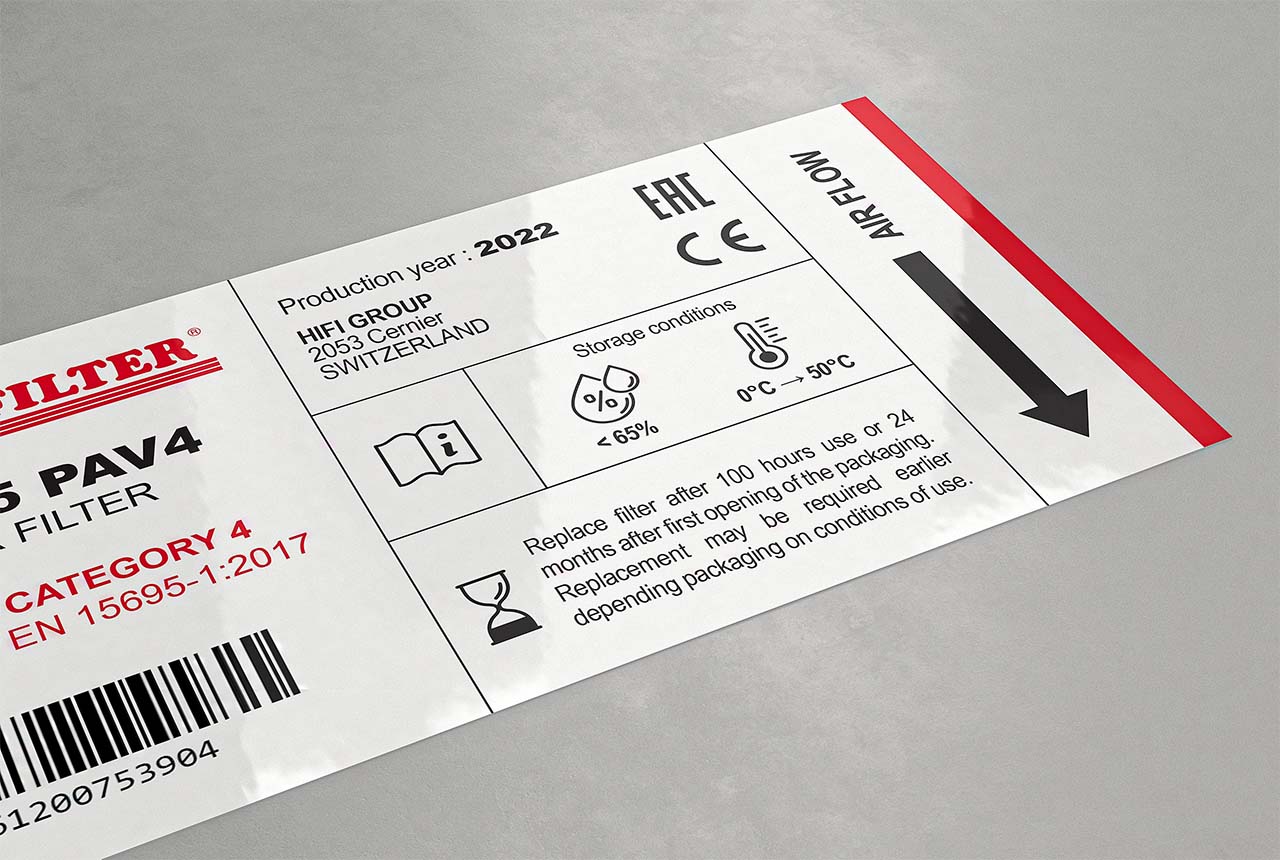

Duration of use

The service life of a PAV4 filter can vary greatly depending on the conditions in which it is used. In general, it lasts 100 hours. After this time, the activated carbon in the filter will become saturated. If saturation occurs, the pores will no longer adsorb toxic particles. Instead, they could release previously captured pollutants into the cabin, creating a risk of exposure. It is therefore essential to change your filters at a frequency appropriate to the conditions of use. In any case, as soon as a suspicious odour appears, it is imperative to change the cabin filter.

⚠️Never blow out an activated carbon filter to extend its life! Compressed air alters the structure of the activated carbon. This would alter the adsorption capacity of the porous material. Do not wash it with water and/or solvents either.