In industrial, commercial and residential buildings, indoor air quality is a major issue. It directly affects the health and well-being of occupants, the durability of facilities and overall energy performance. However, indoor air can be up to five times more polluted than outdoor air, where dust, fine particles, allergens and volatile organic compounds (VOCs).

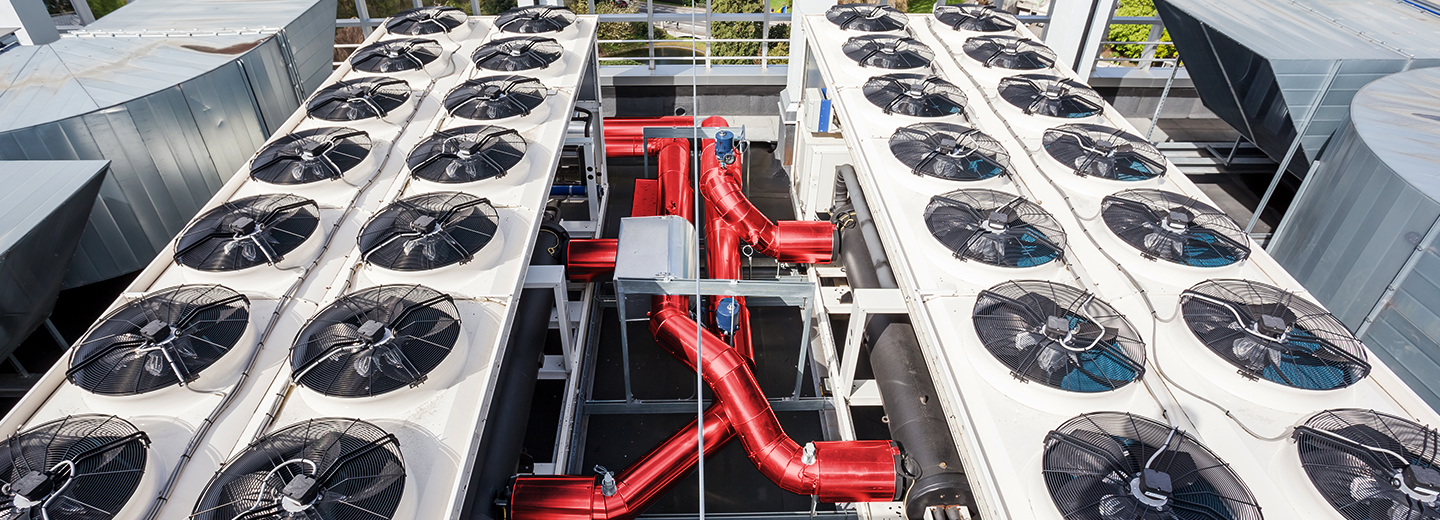

In light of these findings, buildings must incorporate comprehensive air treatment and control solutions. At the heart of these systems, the HVAC (Heat Ventilation Air Conditioning) unit plays an essential role: it ensures the circulation, conditioning and filtration of air to maintain a healthy and balanced indoor environment.

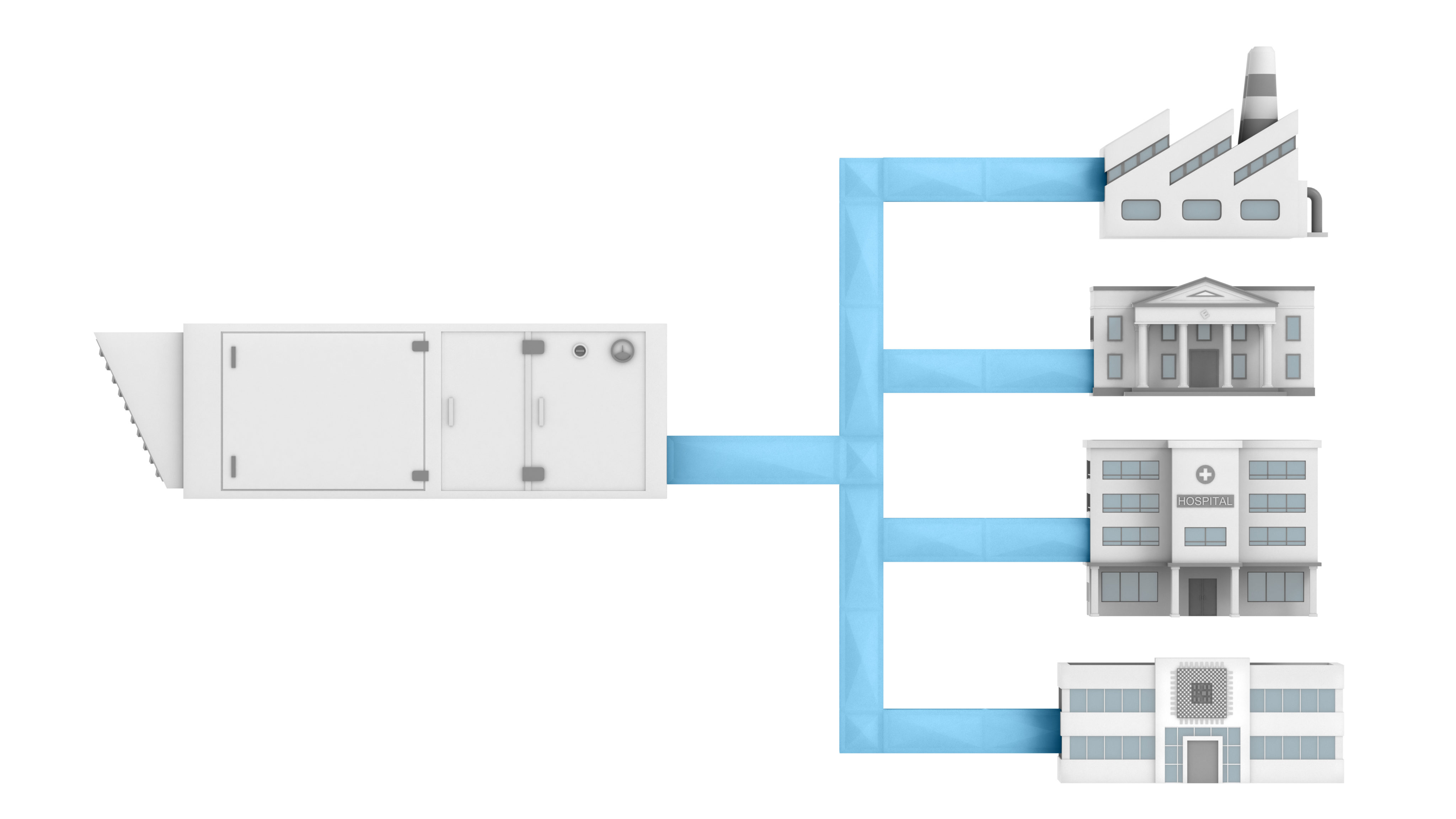

Operation of the HVAC unit

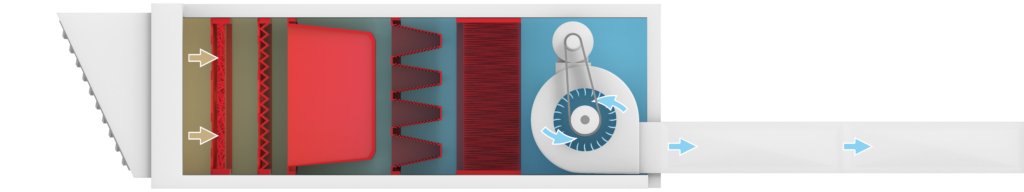

An HVAC unit, or air handling unit, is the lifeblood of a building or industrial facility. It circulates, treats and regulates the air to ensure a healthy and comfortable environment. In practical terms, it draws in fresh air from outside or a mixture of recycled air, passes it through filters that trap dust and impurities, and then conditions it as needed: the air can be heated, cooled, dehumidified or humidified. Fans then distribute it throughout the premises via a network of ducts. At the same time, stale air is extracted and often directed to an exchanger that recovers some of its heat to preheat the incoming air, thereby improving the energy efficiency of the installation. The whole system forms a balance in which each component contributes to maintaining optimal air quality while limiting energy consumption.

Did you know?

In a clean room, a single microscopic particle can be enough to compromise the manufacture of an electronic component or a medicine. ULPA (Ultra Low Penetration Air) filters provide the ultimate barrier against such contamination.

Thanks to their extremely dense mesh, they combine several mechanisms to capture both nanoparticles and coarser dust particles. Indispensable in critical environments such as microelectronics, pharmaceuticals and aeronautics, they guarantee the reliability of processes and the quality of the most sensitive products.

Filtration plays an essential role in the operation of a HVAC unit. While temperature control, air circulation and energy recovery ensure the comfort and efficiency of the system, it is the quality of the filtration that determines its long-term performance. Every cubic metre of air circulating in the building first passes through a filter device: an invisible but essential barrier against dust, fine particles, pollen and micro-organisms.

Effective filtration protects both the occupants and the internal components of the unit, such as fans and heat exchangers, by preventing clogging and maintaining a constant air flow. It thus contributes to the reliability of the system, the control of energy consumption and the reduction of maintenance operations.

HVAC systems incorporate several levels of filtration, adapted to the nature of the pollutants and the regulatory requirements defined by ISO 16890 (air filter classification) and EN1822:2009 (high-efficiency and ULPA filters) standards. These standards guarantee measurable and consistent performance over time, regardless of the context of use.

The consequences of neglected filtration

Clogged or unsuitable filters reduce air flow, increase energy consumption and weaken the entire system. In the long term, this results in reduced performance, higher maintenance costs and poorer air quality.

Choosing the right filter is therefore much more than a question of size or price. The filtration class, allowable pressure drop, replacement frequency and operating conditions must all be taken into account. A correctly sized filter maintains the performance of the HVAC unit, optimises consumption and preserves the service life of the equipment.

To meet these requirements, HIFI FILTER offers a complete range of solutions dedicated to HVAC units: filter mats, pocket filters, panel filters, HEPA/ULPA filters and activated carbon filters. Each product combines filtration efficiency, energy efficiency and durability to ensure clean air and long-lasting operation, even in the most demanding environments.

Air quality control is not just a matter of comfort: it is a key factor in performance and sustainability. With its expertise in filtration,

HIFI FILTER supports HVAC industry players in the design and maintenance of reliable, high-performance systems tailored to each environment.

We offer a

comprehensive range of solutions and personalised support to meet the requirements of all sectors of activity.

Contact our experts for tailored support.