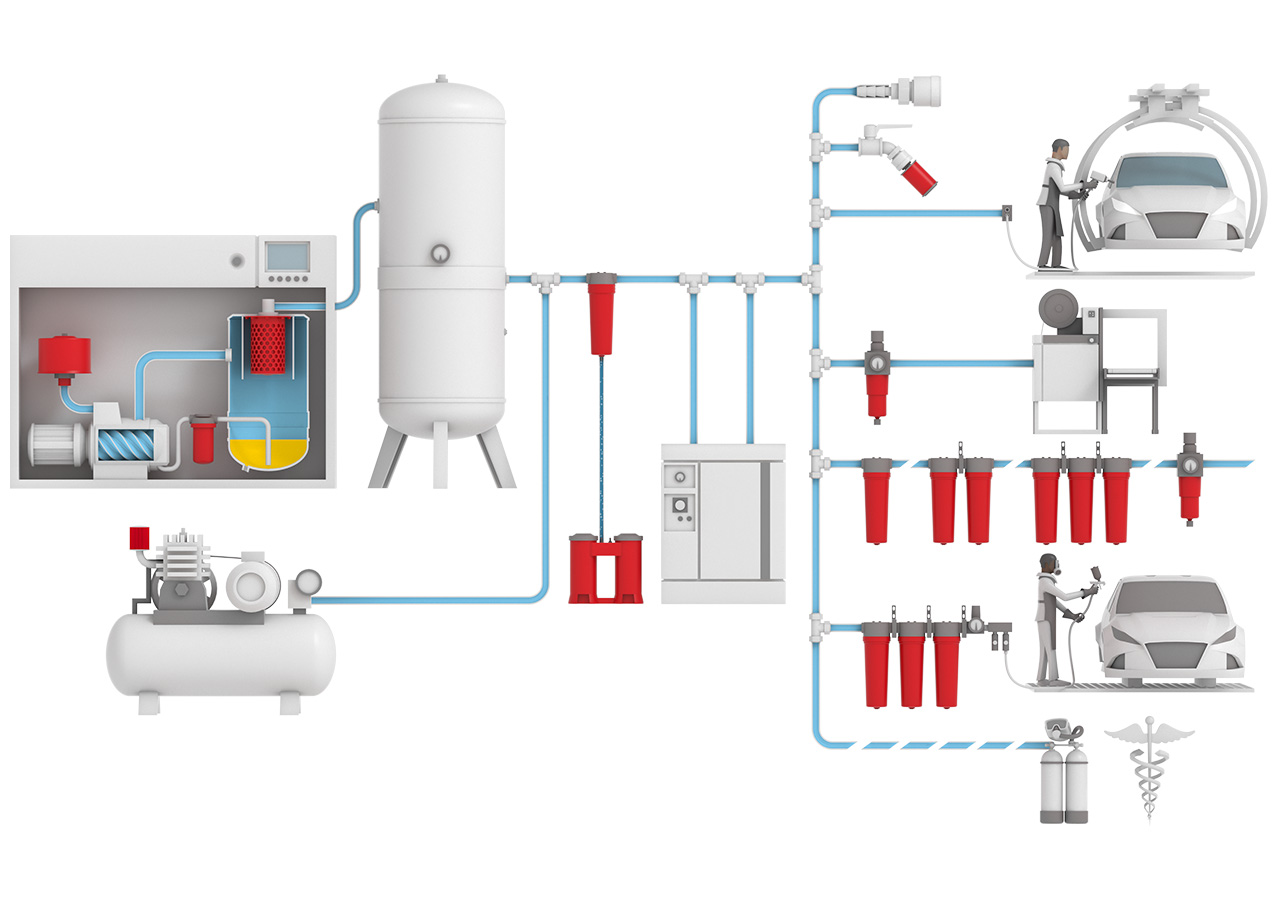

In a compressor, air filters, oil filters and air/oil separators protect the mechanical components and ensure the quality of the outgoing compressed air. During operation, filters wear out in correlation with the working environment and the way they are used. They are affected by dust, temperature variations, humidity, condensate etc. As the compressor is used, the filters become clogged and their performance is reduced.

Ineffective filters can cause unplanned compressor downtime over time. These recurring breakdowns will result in a drop in machine availability and production time, and the company may suffer significant financial losses.

Conversely, high availability of your compressors will result in a high production rate and allow you to generate profits.

In this case, how can downtime be reduced?

Ineffective filters can cause unplanned compressor downtime over time. These recurring breakdowns will result in a drop in machine availability and production time, and the company may suffer significant financial losses.

Conversely, high availability of your compressors will result in a high production rate and allow you to generate profits.

In this case, how can downtime be reduced?