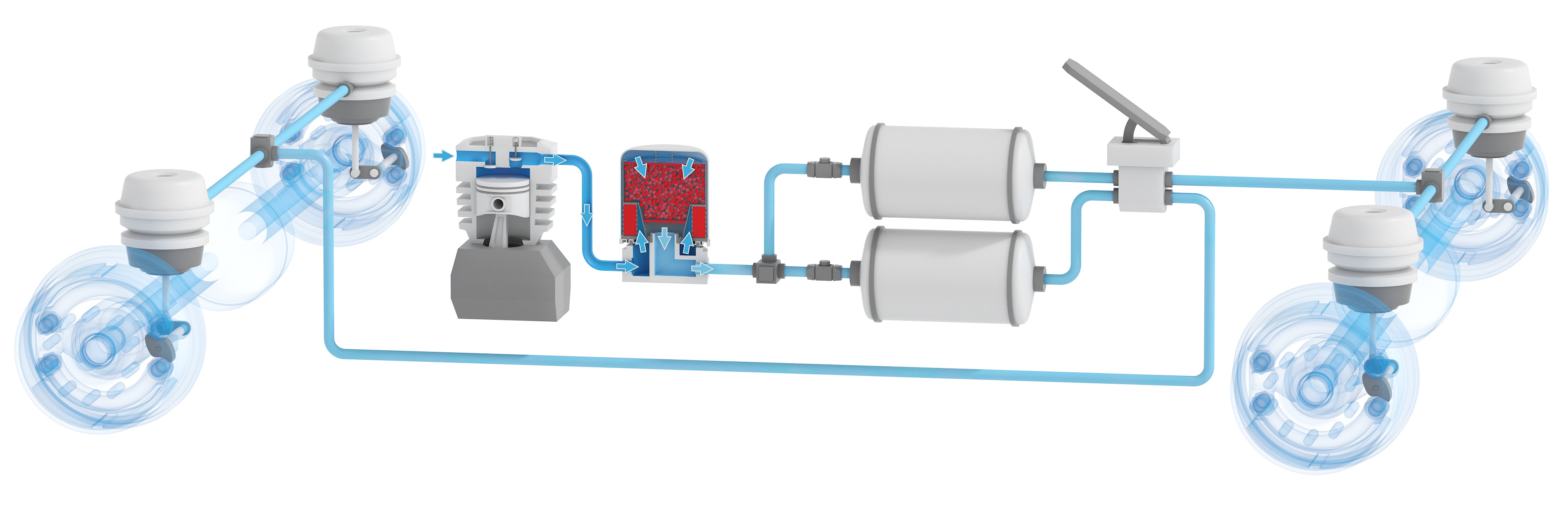

Pneumatic braking systems are essential for heavy vehicles such as trucks and buses, as well as construction and agricultural machinery. Unlike light vehicles, which use hydraulic power, pneumatic braking systems harness compressed air to ensure reliable, powerful braking force.

The importance of filtering compressed air

The compressor draws in air that naturally contains moisture, which condenses when compressed, potentially causing corrosion or freezing of the system. The oil in the circuit can also mix with this water vapour, creating a viscous substance that affects the valves, slows brake response and causes premature wear of the brake linings.

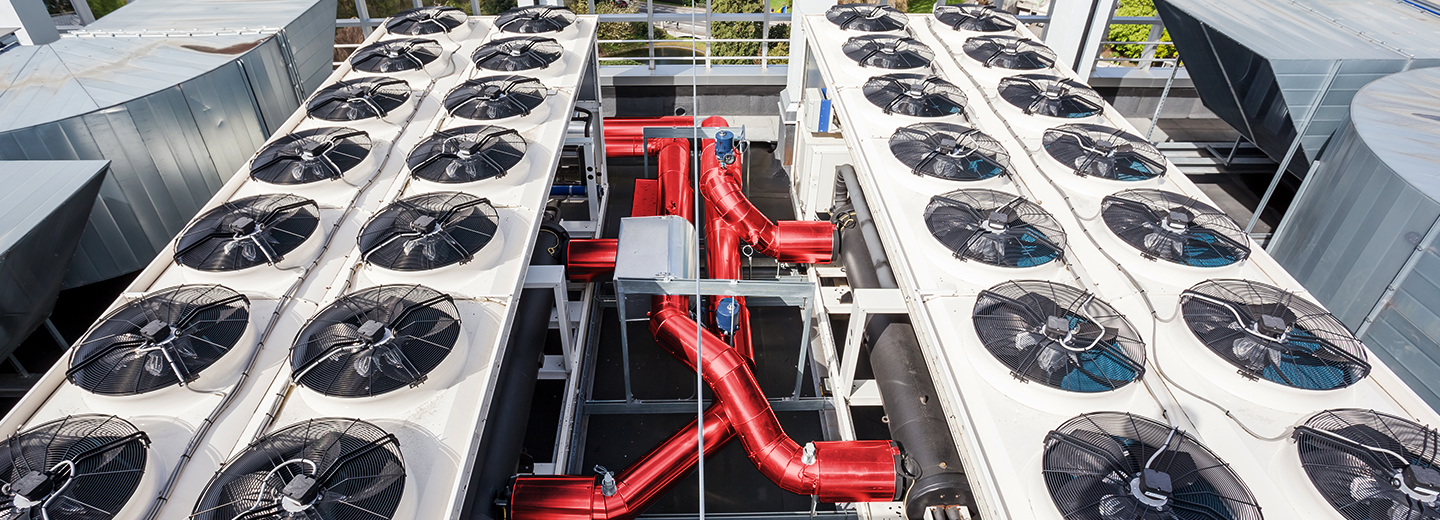

Pneumatic braking systems require a large quantity of clean, dry compressed air per minute to operate correctly. The installation of an air dryer is therefore essential to maintain decontaminated air in the system, guaranteeing your safety and braking efficiency.

How an air dryer works

An air dryer contains silica gel granules, a drying material capable of absorbing water vapours.

Some dryers also incorporate a coalescing media to retain oil and solid particles.

Replacing the air dryer

Over time, the desiccant filter elements become saturated and lose their effectiveness, requiring regular replacement. The frequency of replacement depends on the manufacturer's recommendations and the vehicle's operating conditions.

There are a number of signs that a replacement is required, such as an excessive amount of water at the bleed valve, meaning that the desiccant material is saturated, or a bleed valve stuck in the open position, slowing down the build-up of pressure in the system. A visual inspection may reveal damaged cartridges or twisted hoses, also indicating the need for a change. To prevent costly breakdowns and ensure safe operation, it is therefore crucial to follow manufacturers' recommended maintenance practices, use quality spare parts and carry out regular inspections.

Air dryers for all your needs

HIFI FILTER® offers a wide range of air dryers, suitable for all types of vehicles and equipment. Whether for trucks, buses, construction or agricultural machinery, our solutions ensure clean, dry compressed air, guaranteeing optimum performance and increased safety for your air braking systems.