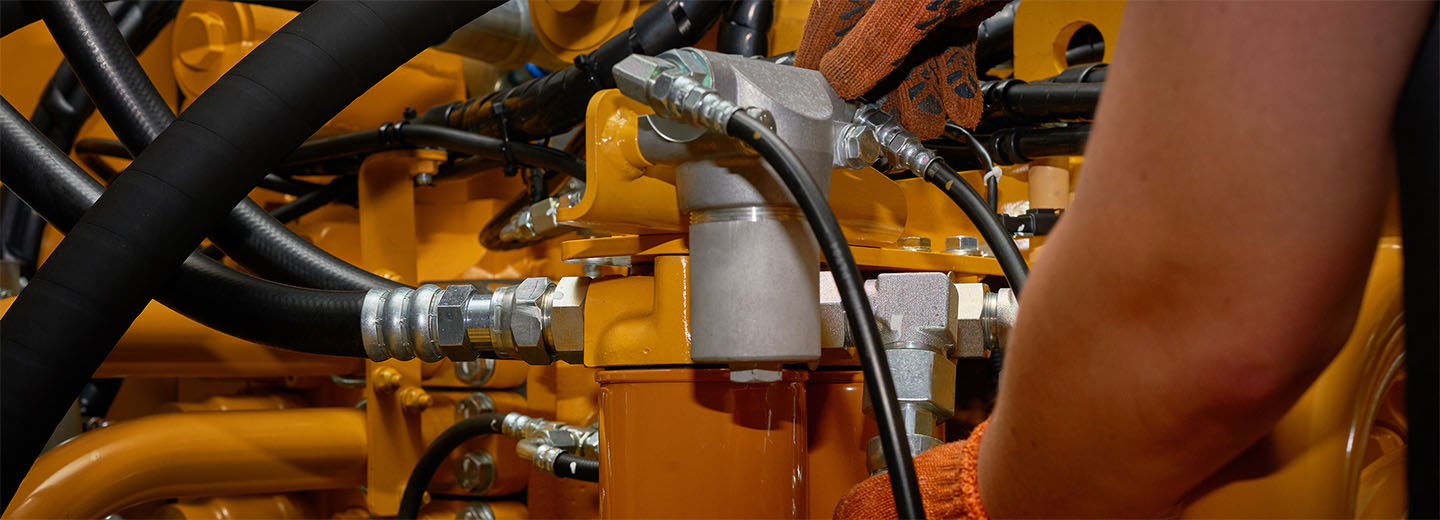

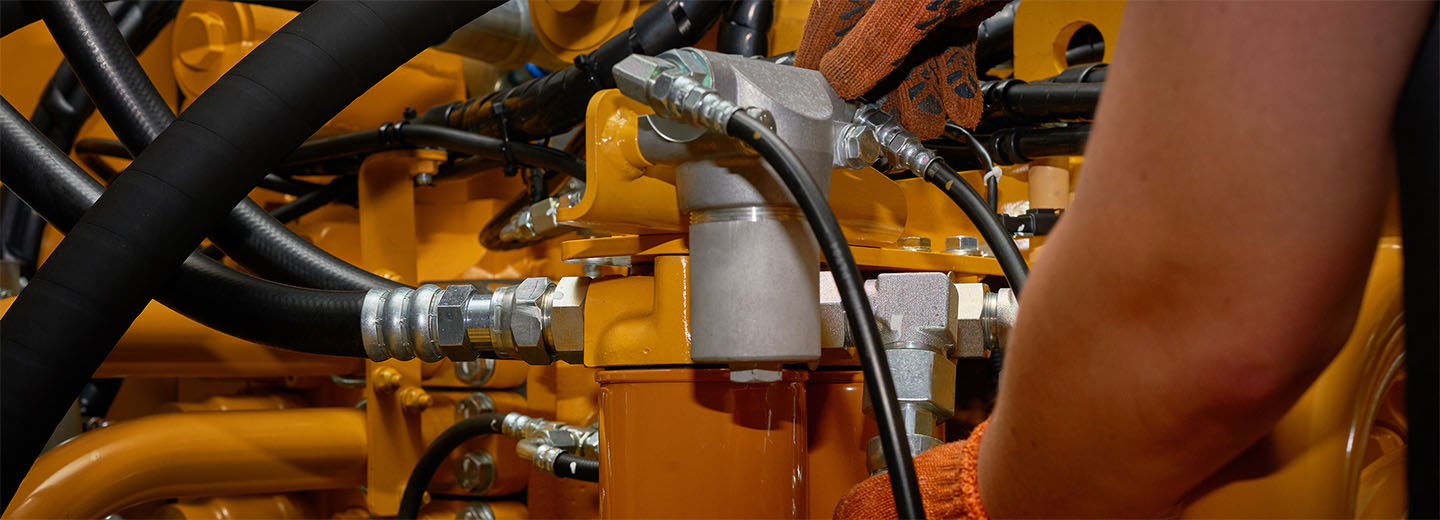

The properties of a hydraulic fluid include viscosity, resistance to temperature variations and fire resistance.

- Viscosity refers to resistance to flow and is determined by the viscosity index, based on the change in thickness of the fluid according to temperature variations. It is essential to use a fluid with a viscosity suited to the equipment: too viscous, it can cause loss of efficiency and cavitation; too fluid, it increases the risk of seizure and breakage.

- Resistance to temperature variations corresponds to the temperature range within which the fluid can be used without losing its properties.

- Fire resistance refers to a fluid's ability to minimise the risk of combustion, assessed by its flash point, ignition point and self-ignition point.

A hydraulic fluid also has environmental characteristics, as well as oxidation and water resistance properties.

These hydraulic fluids are susceptible to contamination by particles, water or gas, which can compromise system performance. To minimise these risks, installing suitable filters on the various parts of the hydraulic circuit is an effective solution. To find out more, please consult our dedicated article: [...]