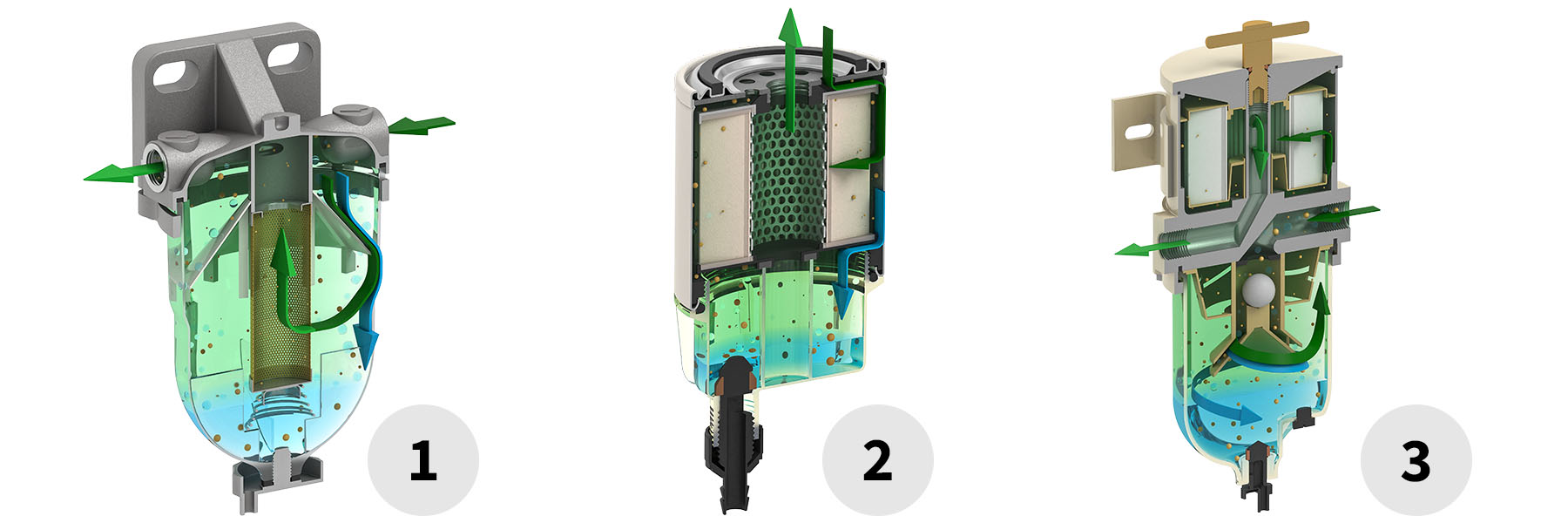

2. WATER SEPARATORSHIFI FILTER® decanters equipped with a filtering element decontaminate your fuel by means of decanting and a media. Our catalogue offers two types of filter solutions under this name:

- Filters with a decanter bowl: control the water level and drain the excess via its drain

- Filters with a bleed screw: without visual control and in accordance with the manufacturer's maintenance recommendations, unscrew regularly and empty the water accumulated at the bottom of the flange.

The media installed in these filters is mostly two-layer, such as the

MO 1400. Dual layer media uses a cellulose media for pre-filtration and a polyester media for water separation. The purpose of this technology? To optimise the purity of your fuel and ensure the protection of your diesel engine.